The Vital Role of a China Machining Lathe Parts Factory in Metal Fabrication

In today's highly competitive manufacturing landscape, businesses are continuously seeking ways to enhance their production capabilities and achieve greater efficiency. One significant player in this arena is the China machining lathe parts factory, which provides crucial components for numerous applications across various industries.

Understanding Machining and Lathe Parts

Machining is a manufacturing process where material is removed from a workpiece to achieve desired dimensions and surface finish. Lathe machining specifically involves rotating a workpiece against a cutting tool, which shapes the material into precise forms. This process is central to metal fabrication and is used extensively to create components for:

- Aerospace applications

- Automotive manufacturing

- Industrial machinery

- Electronics

- Medical devices

The parts produced by a China machining lathe parts factory are essential for the functionality and reliability of the end products. Whether it’s a small gear or a complex housing unit, these machined components support the intricate systems that drive modern technological solutions.

The Benefits of Sourcing from China

Certainly, one might wonder why businesses choose to source their machining lathe parts from China. The reasons are multifaceted and compelling, including:

1. Cost Efficiency

China is known for its competitive pricing due to lower labor costs and an established supply chain. This enables China machining lathe parts factories to offer high-quality components at an affordable price, allowing businesses to optimize their budgets.

2. Advanced Technology

Chinese factories often invest heavily in modern technology and advanced machinery. This ensures that lathe parts are produced using cutting-edge techniques, resulting in enhanced precision and reduced waste.

3. Scalability

Manufacturers often require rapid production to meet market demands. A reputable China machining lathe parts factory can scale up operations quickly, providing the flexibility needed to handle large orders without compromising quality.

4. Expertise and Experience

With years of experience in the industry, many Chinese manufacturers have developed substantial expertise in machining processes. They understand the nuances of different materials and can suggest the best practices for various applications.

The Manufacturing Process in a China Machining Lathe Parts Factory

The manufacturing process in a typical China machining lathe parts factory involves several key steps, each crucial for ensuring high-quality output:

1. Design and Engineering

The process begins with detailed design and engineering, where specifications provided by clients are transformed into production-ready designs using CAD (Computer-Aided Design) software. This stage is critical, as it lays the foundation for subsequent manufacturing activities.

2. Material Selection

Choosing the right material is essential for the intended application. Factories typically offer a variety of metals, including:

- Aluminum

- Stainless steel

- Copper

- Alloys

Each material has specific characteristics that affect the performance of the final product.

3. Machining Process

Once the design and materials are finalized, the machining process commences. This can involve several techniques, such as:

- Turning

- Milling

- Drilling

- Grinding

Using CNC (Computer Numerical Control) machines, the lathe parts are precisely shaped according to the specifications, ensuring consistency across production runs.

4. Quality Control

Quality assurance is a critical component in a China machining lathe parts factory. Each batch of products undergoes rigorous inspection and testing, utilizing both manual checks and automated systems to ensure adherence to the required standards. This includes dimensional checks, surface finish evaluations, and functional testing to prevent defects.

5. Finishing Processes

After machining, finishing processes such as polishing, anodizing, or coating may be applied to enhance the parts' appearance and performance. This final touch ensures that the components are not only functional but also meet aesthetic requirements where applicable.

Applications of Lathe Parts in Various Industries

The versatility of lathe parts manufactured in a China machining lathe parts factory cannot be understated. Numerous industries benefit from these components:

Aerospace

In the aerospace sector, precision and reliability are paramount. Lathe parts are used in everything from aircraft engines to landing gear, where they play a critical role in ensuring safety and performance.

Automotive

The automotive industry relies heavily on machined parts for crucial components ranging from engine blocks to transmission systems. The high volume of production necessitates a reliable supply of quality lathe parts to keep assembly lines running efficiently.

Medical Devices

In the healthcare industry, precision-engineered lathe parts are essential for medical devices. From surgical instruments to diagnostic equipment, the quality of these components can directly impact patient outcomes.

Industrial Machinery

Industrial machinery encompasses a wide range of equipment, and lathe parts are key components in various machines that facilitate manufacturing processes, from lathes and milling machines to conveyor systems.

Electronics

In the electronics sector, the demand for precision components has grown significantly. Lathe parts are utilized in housing for devices, connectors, and various electronic assemblies, where accuracy is essential.

Choosing the Right China Machining Lathe Parts Factory

When selecting a China machining lathe parts factory to partner with, businesses should consider several factors to ensure they make the best decision:

- Reputation: Research prospective factories for reviews and testimonials. A well-established manufacturer with a solid track record is likely to produce quality parts.

- Certifications: Look for factories that have ISO certification or other relevant accreditations, as these indicate adherence to quality standards.

- Technology: Assess the technological capabilities of the factory. Advanced machinery indicates a commitment to quality and efficiency.

- Customer Service: A responsive and helpful customer service team can contribute significantly to a smooth partnership.

- Flexibility: Consider whether the factory can adapt to your specific needs regarding batch sizes, materials, and lead times.

Future Trends in Machining and Fabrication

The future of machining and fabrication is poised for exciting developments, particularly as technology continues to advance. Here are some trends to keep an eye on:

1. Automation

Automation technology is transforming the machining landscape, allowing factories to increase productivity while reducing labor costs. Robotics and automated processes will likely become standard practice in China machining lathe parts factories.

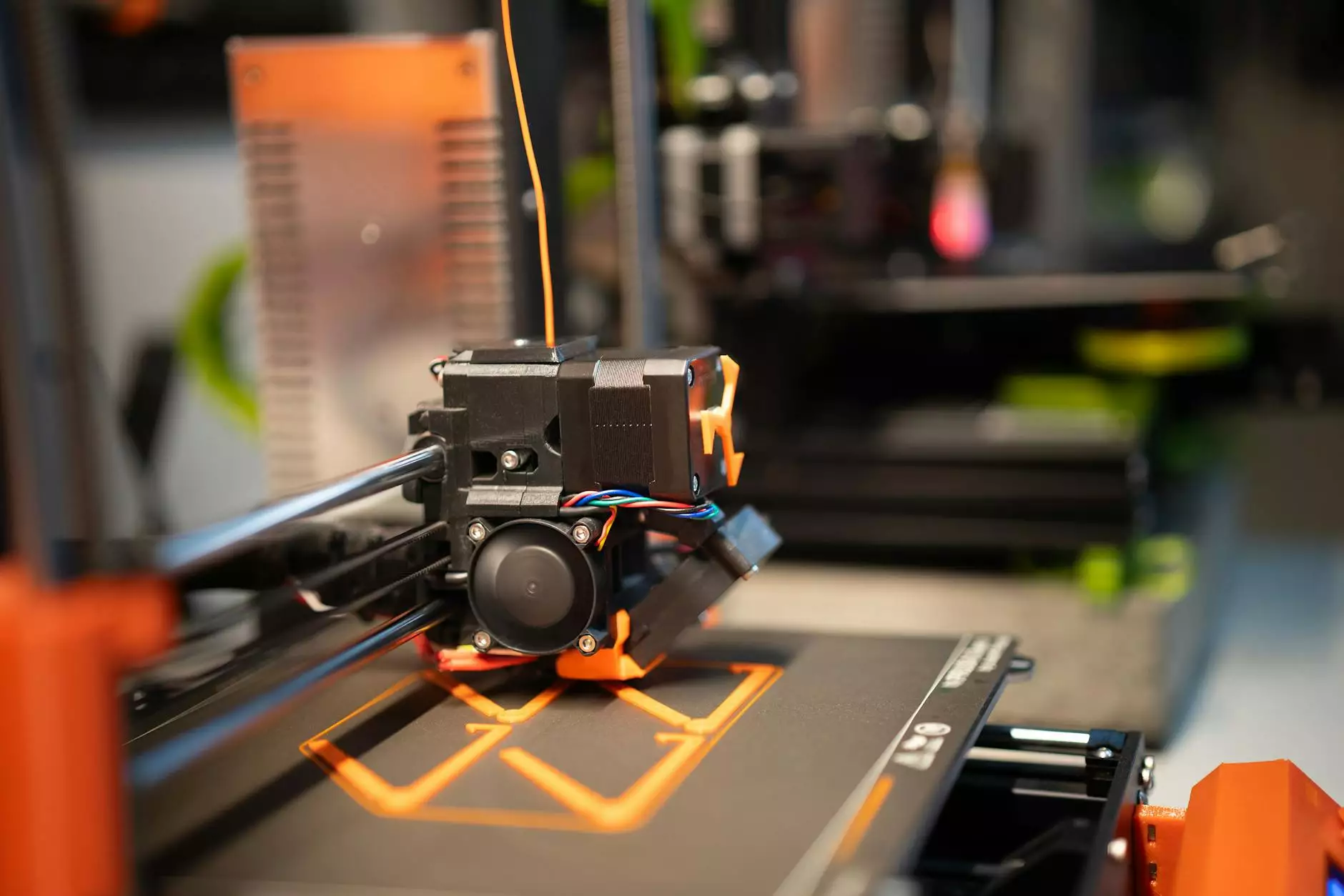

2. Additive Manufacturing

While traditional machining is vital, additive manufacturing (3D printing) is emerging as a complementary process. This technology enables the production of complex parts that would be difficult or impossible to achieve through conventional machining methods.

3. Sustainability

As environmental concerns grow, many manufacturers are adopting sustainable practices. Factories are focusing on reducing waste, recycling materials, and using eco-friendly processes in their operations.

4. Customization

The demand for customized components is increasing as businesses seek tailored solutions to meet specific challenges. Advanced CNC machining and technologies will support this trend by allowing for more flexibility in production.

Conclusion

In conclusion, a China machining lathe parts factory plays a pivotal role in the global manufacturing ecosystem. By understanding the intricacies of machining and the benefits of sourcing from China, businesses can make informed decisions that enhance their production capabilities and product quality. Whether it's for aerospace, automotive, or medical applications, the precision and expertise offered by these factories are indispensable in today's fast-paced market.

Choosing the right factory not only ensures quality components but can also contribute to the overall success of a business. Embracing the latest trends and technologies will further position firms at the forefront of the industry, paving the way for sustained growth and innovation in the years to come.