Understanding **3D Rapid Prototyping**: Transforming Metal Fabrication

In today's fast-paced business landscape, 3D rapid prototyping has emerged as a transformative technology that significantly enhances product development across various industries, particularly in metal fabrication. The ability to quickly turn ideas into tangible prototypes allows businesses to innovate faster and improve their processes. This article delves into the intricacies of 3D rapid prototyping, its benefits, processes, and how it reshapes the future of metal fabrication.

The Evolution of Prototyping

Prototyping has always been an integral part of the product development cycle. Traditionally, it involved manual techniques that required significant time and resources. With the advent of digital technologies, we have seen significant advancements leading to the 3D rapid prototyping techniques we see today. This evolution not only allows for faster production but also enables greater precision and flexibility in design.

What is 3D Rapid Prototyping?

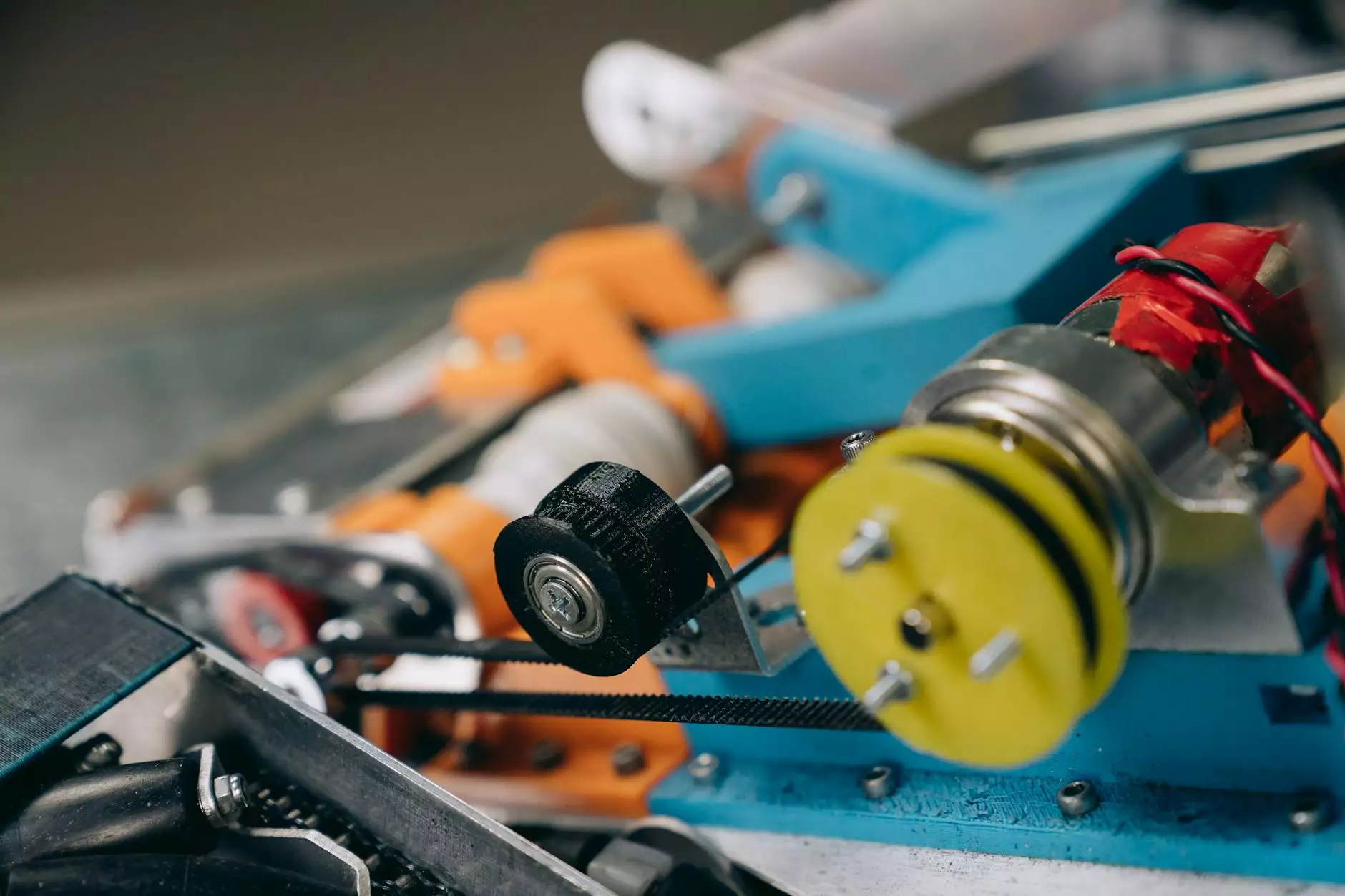

At its core, 3D rapid prototyping is a technology that allows for the quick fabrication of a physical part, model, or assembly using three-dimensional computer-aided design (CAD) data. Various techniques, such as additive manufacturing, are employed to create prototypes quickly and efficiently. Some popular methods include:

- Fused Deposition Modeling (FDM): This process involves layering thermoplastic materials to create prototypes.

- Stereolithography (SLA): A technique that uses UV light to cure resin into hardened plastic.

- Selective Laser Sintering (SLS): Employs a laser to sinter powdered material, binding it together to form a solid structure.

Benefits of 3D Rapid Prototyping in Metal Fabrication

The integration of 3D rapid prototyping in metal fabrication opens up a myriad of benefits, including:

1. Accelerated Product Development

One of the most significant advantages is the speed at which prototypes can be produced. This rapid turnaround allows businesses to test ideas and make necessary adjustments quickly.

2. Cost Efficiency

By reducing the time spent on prototyping, companies can significantly lower their costs associated with product development. The need for extensive tooling is diminished, allowing for lower material costs.

3. Enhanced Accuracy and Precision

Technologies used in 3D rapid prototyping offer high precision, which is essential in metal fabrication where tolerances need to be exact to ensure functionality.

4. Greater Design Freedom

Unlike traditional manufacturing methods, 3D rapid prototyping allows for more intricate designs and complex geometries that would be difficult or impossible to achieve with conventional techniques.

5. Improved Collaboration and Communication

Having a physical prototype allows teams to visualize the product better, leading to improved communication among stakeholders and reducing the risk of misinterpretation in the design phase.

The 3D Rapid Prototyping Process

Understanding the step-by-step process of 3D rapid prototyping in metal fabrication is crucial for businesses aiming to implement this technology effectively:

Step 1: Design Development

The first step involves creating a 3D model using CAD software. This digital model serves as the framework for the prototype.

Step 2: Preparation

Once the design is complete, it is prepared for printing. This involves converting the CAD file into a format that the prototyping machine can understand (often STL).

Step 3: Prototyping

With the preparation complete, the actual prototyping begins. Depending on the chosen method, materials are layered, sintered, or deposited according to the specifications outlined in the digital model.

Step 4: Post-Processing

After the prototype is complete, it often requires post-processing, which may include cleaning, sanding, or painting to achieve the desired finish.

Step 5: Testing and Iteration

Finally, the prototype is tested in real-world conditions. Based on the feedback received, businesses can iterate on the design, making modifications as necessary before moving into full-scale production.

Challenges in 3D Rapid Prototyping

While 3D rapid prototyping offers numerous benefits, it is not without its challenges. Understanding these can help businesses plan effectively:

Material Limitations

Although advancements have been made, some materials may not yet be compatible with 3D printing technologies, limiting the options for metal fabrication.

Technical Expertise

Implementing 3D rapid prototyping requires skilled personnel who understand both the technology and the design processes. There may be a learning curve for teams transitioning from traditional methods.

Initial Investment Costs

The initial investment in machinery and technology can be high, which may deter some businesses from adopting these methods. However, the long-term savings often justify the upfront costs.

Future Trends in 3D Rapid Prototyping

The future of 3D rapid prototyping in metal fabrication is bright, with several trends shaping its evolution:

1. Advancements in Materials

Continuous research into new materials, especially high-performance alloys for metal fabrication, is expected to enhance the capabilities of 3D rapid prototyping.

2. Automation and AI Integration

Integrating artificial intelligence and automation will streamline the prototyping process further. Predictive analytics may optimize materials and processes based on real-time data.

3. Customization and Personalization

As consumer demand shifts toward personalization, 3D rapid prototyping will enable businesses to offer custom solutions at scale without extensive retooling.

4. Eco-Friendly Solutions

With increasing awareness of environmental impact, businesses will seek 3D rapid prototyping methods that are sustainable, focusing on recycling materials and minimizing waste.

Conclusion

In conclusion, 3D rapid prototyping is revolutionizing the metal fabrication industry by allowing businesses to innovate faster, reduce costs, and improve product quality. As technology continues to advance, the possibilities are endless, paving the way for smarter, more efficient manufacturing processes. Embracing this technology positions businesses not only to compete but to lead in their markets. For companies looking to enhance their production capabilities, Deep Mould stands as a reputable partner in metal fabrication, ready to integrate 3D rapid prototyping into your supply chain for unparalleled results.

For more information on how Deep Mould can help your business leverage 3D rapid prototyping, please visit our website at deepmould.net.

3 d rapid prototyping